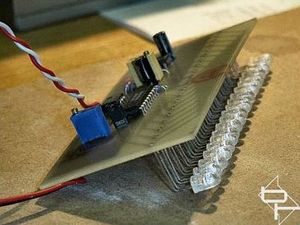

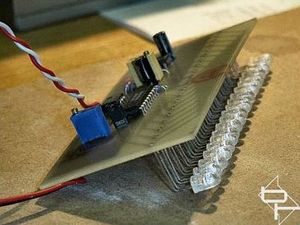

At this stage of construction it was time to have some fun. Enter the HDD and power light. This is a modified version of my "Knight Rider" HDD activity meter. The modifications mainly consisted of redesigning the PCB to accept 5mm LEDs and removing any surplus tracks.

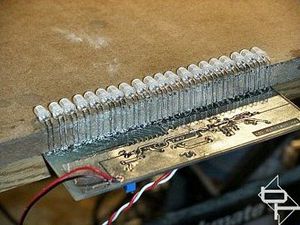

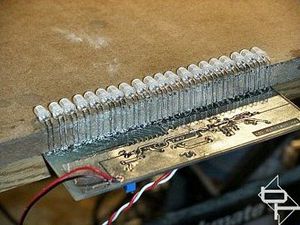

The LED leads were left long and bent as shown. You will soon see why.

The LEDs were also ground flat. The LED diameter is 6mm at its widest and they have to sit in 5.5mm thick Acrylic! As you can see this a BiT-Tech design through and through.

A slot to take the LEDs was routed into the case base panel. Initially it was intended that the acrylic, which is smoked, would be diffused to give a "light bar" effect. Unfortunately, due to the optical characteristics of the smoked Acrylic, the effect was rather poor. So we decided to make our own diffuser from green tinted Acrylic. I had a thin strip left over from a previous project. The strip was routed into shape and the diffused using 400 grade wet and dry paper. The LED slot was routed to size and shape to allow the diffuser strip to be fixed in place.

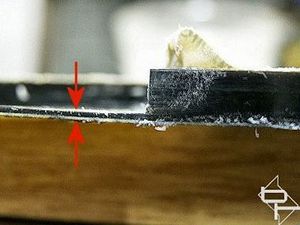

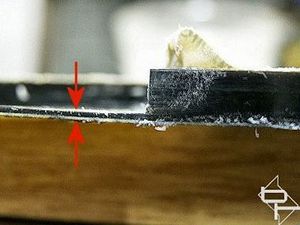

To give some idea of the accuracy of cutting involved, the picture below shows how little of the Acrylic thickness of the base plate was left after routing. Less than 0.5mm. Half of the thickness in the picture is made up from the protective paper on the Acrylic. The diffuser fitted perfectly flush and was glued in to place.

The LED leads were left long and bent as shown. You will soon see why.

The LEDs were also ground flat. The LED diameter is 6mm at its widest and they have to sit in 5.5mm thick Acrylic! As you can see this a BiT-Tech design through and through.

A slot to take the LEDs was routed into the case base panel. Initially it was intended that the acrylic, which is smoked, would be diffused to give a "light bar" effect. Unfortunately, due to the optical characteristics of the smoked Acrylic, the effect was rather poor. So we decided to make our own diffuser from green tinted Acrylic. I had a thin strip left over from a previous project. The strip was routed into shape and the diffused using 400 grade wet and dry paper. The LED slot was routed to size and shape to allow the diffuser strip to be fixed in place.

To give some idea of the accuracy of cutting involved, the picture below shows how little of the Acrylic thickness of the base plate was left after routing. Less than 0.5mm. Half of the thickness in the picture is made up from the protective paper on the Acrylic. The diffuser fitted perfectly flush and was glued in to place.

MSI MPG Velox 100R Chassis Review

October 14 2021 | 15:04

Want to comment? Please log in.